| Author |

Message |

|

|

| |

Post subject: |

Re: 3D printing |

|

|

Well, I've discovered that buying cheap is not always buying "Smart". To wit - I thought that I'd save some money by using "cheapo" no-name paper towels from Wally World rather than the rather expensive brand of towel (Bounty). Turns out that this was a BIG mistake - the cheapos don't absorb anything nearly as well as the expensive brand and as a result, there is no savings in cost, but a large expense in the usage to clean up the same amount of printer parts that is required after each print run. Attachment:

AC Photon Mono X 6K Printer_2.jpeg [ 113.44 KiB | Viewed 3249 times ]

AC Photon Mono X 6K Printer_2.jpeg [ 113.44 KiB | Viewed 3249 times ]

Normally, I always clean the build platform completely and then the area around the printer that may have had resin spill on it while removing the build platform & parts from the printer. Of course, if you're detanking the vat that will also require quite a few paper towels, so the entire effort can get somewhat "towelly"!! I still have two rolls of the cheap stuff, so will suffer thru that and then go back to buying a bundle of Bounty as those towels really work the best. Hope this resonates with others doing 3D printing and gives some practical guidence. Hank Well, I've discovered that buying cheap is not always buying "Smart". To wit - I thought that I'd save some money by using "cheapo" no-name paper towels from Wally World rather than the rather expensive brand of towel (Bounty). Turns out that this was a BIG mistake - the cheapos don't absorb anything nearly as well as the expensive brand and as a result, there is no savings in cost, but a large expense in the usage to clean up the same amount of printer parts that is required after each print run.

[attachment=0]AC Photon Mono X 6K Printer_2.jpeg[/attachment]

Normally, I always clean the build platform completely and then the area around the printer that may have had resin spill on it while removing the build platform & parts from the printer. Of course, if you're detanking the vat that will also require quite a few paper towels, so the entire effort can get somewhat "towelly"!! I still have two rolls of the cheap stuff, so will suffer thru that and then go back to buying a bundle of Bounty as those towels really work the best.

Hope this resonates with others doing 3D printing and gives some practical guidence.

Hank

|

|

|

|

Posted: Fri Dec 22, 2023 1:05 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

have printed some twin bofors for 1/700 - 1/600 scale  have printed some twin bofors for 1/700 - 1/600 scale

[url=https://postimg.cc/CRsswm5h][img]https://i.postimg.cc/t4LStcHx/40.jpg[/img][/url]

|

|

|

|

Posted: Mon Dec 04, 2023 5:30 am |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

Merci Iceman I love your Bretagne build, merci beaucoup for sharing it with us here. Addendum: Printed Constellation's 2nd cutter... Attachment:

File comment: 2nd cutter stacked on the 1st cutter alongside the launch

con20231219h.jpg [ 204.98 KiB | Viewed 3350 times ]

con20231219h.jpg [ 204.98 KiB | Viewed 3350 times ]

Merci Iceman

I love your Bretagne build, merci beaucoup for sharing it with us here.

Addendum: Printed Constellation's 2nd cutter...

[attachment=0]con20231219h.jpg[/attachment]

|

|

|

|

Posted: Sun Nov 19, 2023 4:07 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

Very nice printing at this scale ! 1/36.  Very nice printing at this scale ! 1/36. :thumbs_up_1:

|

|

|

|

Posted: Sun Nov 19, 2023 1:04 am |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

Bought a new Elegoo Mars 3 the beginning of November and started printing parts...for ConstellationAttachment:

File comment: Rigging-screws (turnbuckles) for Constellation

con20231016d.jpg [ 3.04 MiB | Viewed 4403 times ]

con20231016d.jpg [ 3.04 MiB | Viewed 4403 times ]

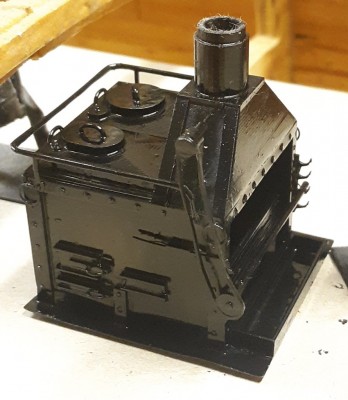

A stove for MacedonianAttachment:

File comment: 1:36 scale Brodie stove for a 38 gun ship

mac20231115.png [ 1.8 MiB | Viewed 4403 times ]

mac20231115.png [ 1.8 MiB | Viewed 4403 times ]

Attachment:

File comment: Stove with a coat of paint

20231116_173720.jpg [ 134.08 KiB | Viewed 4403 times ]

20231116_173720.jpg [ 134.08 KiB | Viewed 4403 times ]

The STL for the stove is on Thingiverse

[size=150]Bought a new Elegoo Mars 3 the beginning of November and started printing parts...[/size]

for [b]Constellation[/b]

[attachment=2]con20231016d.jpg[/attachment]

[size=150]A stove for [b]Macedonian[/b][/size]

[attachment=1]mac20231115.png[/attachment]

[attachment=0]20231116_173720.jpg[/attachment]

The STL for the stove is on Thingiverse

|

|

|

|

Posted: Sat Nov 18, 2023 9:56 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

Having cleaned everything up and recalc'd Zero on the build platform, I've begun a new print. I watched/listened to the printer for the first 20 layers being printed at which point the bottom of the parts were completed and it's now building up for the vertical elements - so far everything is working smoothly. This leads me to believe that the problem was that in not squeegeeing the FEP after the last print, somehow a "footprint" was left on the FEP surface that caused the resin to stick to it on the subsequent print - I will be sure to do this small chore from here on out. 25 lashes from The Admiral would normally be the suitable punishment for committing a PCFI, but since she DOESN'T know this occurred, I've spared myself both the embarrassment and beating...a win-win situation as I see it!!!!!  Hank Having cleaned everything up and recalc'd Zero on the build platform, I've begun a new print. I watched/listened to the printer for the first 20 layers being printed at which point the bottom of the parts were completed and it's now building up for the vertical elements - so far everything is working smoothly. This leads me to believe that the problem was that in not squeegeeing the FEP after the last print, somehow a "footprint" was left on the FEP surface that caused the resin to stick to it on the subsequent print - I will be sure to do this small chore from here on out.

25 lashes from The Admiral would normally be the suitable punishment for committing a PCFI, but since she DOESN'T know this occurred, I've spared myself both the embarrassment and beating...a win-win situation as I see it!!!!! :big_grin:

Hank

|

|

|

|

Posted: Sun Sep 24, 2023 1:35 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

|

Yes, your centre piece must be sucking.

I haven't been printing directly onto the plate for a long time. The supports allow the air to pass inside the piece. Even with supports, you have to make sure there's enough event in the piece to avoid this phenomenon.

I also run the spatula over the FEP film in the vat full of resin to see if there are any pieces of the previous print stuck to the film.

Yes, your centre piece must be sucking.

I haven't been printing directly onto the plate for a long time. The supports allow the air to pass inside the piece. Even with supports, you have to make sure there's enough event in the piece to avoid this phenomenon.

I also run the spatula over the FEP film in the vat full of resin to see if there are any pieces of the previous print stuck to the film.

|

|

|

|

Posted: Sat Sep 23, 2023 4:14 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

Potential Catastrophic Failure Incident (PCFI)I had a print going today and as I was nearby, could hear what sounded like a different noise coming from the printer. Upon inspection, I found that the build plate was grinding away trying to raise and could not. Turned off the printer immediatley and began to mentally try to figure out what was happening. The print was only about 5 minutes into it's run (6 hours total) and so was basically finishing the bottom layers of the print. Somehow, it was stuck on the FEP and wouldn't release. So, what to do???? I began by removing the 4 bolts holding the bracket of the build platform to the lifting arm which released the arm from the bracket and allowed me to slide off the bracket. I then raised the lifting arm up to almost the top to make clear room to work below. I then removed the vat (w/building platform, etc.) and emptied the resin back into the jug (filtering, of course  ), and then addressed the problem of the build platform stuck to the FEP. This was the 2nd print today of the same part which I had printed successfully and removed not long before starting the new print run. I don't know the reason, but once the vat was empty, I could put my fingers under it and slightly push the FEP up thus breaking the seal between the FEP and the part - I was thus able to remove the parts without damaging the FEP. Attachment:

Failed FCD on Build Platf.jpeg [ 444.92 KiB | Viewed 4504 times ]

Failed FCD on Build Platf.jpeg [ 444.92 KiB | Viewed 4504 times ]

You can see the footprint of the part where suction held the part to the FEP. I then proceeded to clean the vat and get it ready to print. In addition, the LCD screen & protective sheet on top were unaffected which was a major concern of mine - Attachment:

LCD Screen wSheet.jpeg [ 412.57 KiB | Viewed 4504 times ]

LCD Screen wSheet.jpeg [ 412.57 KiB | Viewed 4504 times ]

This will give me an opportunity to clean the vertical elevation rod before doing the normal resetting of the build platform (Z Lift 0 Setting). Before I try printing this part again, I am still trying to figure out why this occurred - only 2 causes seem plausible: 1) The location (X/Y) of where the print was located within the printing parameters caused a suction to develop at that spot, or 2) Printing the center of the part directly on the build platform with no supports had created a vacuum when the print began printing the 1st layer on the FEP and this vacuum was just as strong as the resin layer on the build platform which brought things to a halt. I'm glad I was there in the shop when this happened. Had I not been, I'm sure the printer would have gone up in smoke at some point and that would have been an expensive failure!! One item to note -l I did NOT take the plastic squeegee and drag it across the FEP to basically "clear" that area of the FEP prior to beginning the next print run. It's quite possible that had I done that, this incident would not have happened. I've printed other parts directly on the build platform and never had an issue with sticking to the FEP, as well. Always a first time...  I'm leaning towards redesigning the part adding in a few slots in the circular center disc in order to break a potential suction being created again. But, this is a gamble at best. Any ideas from other 3D designer/printer/modelers is welcomed.

[b][u]Potential Catastrophic Failure Incident (PCFI)[/u][/b]

I had a print going today and as I was nearby, could hear what sounded like a different noise coming from the printer. Upon inspection, I found that the build plate was grinding away trying to raise and could not. Turned off the printer immediatley and began to mentally try to figure out what was happening. The print was only about 5 minutes into it's run (6 hours total) and so was basically finishing the bottom layers of the print. Somehow, it was stuck on the FEP and wouldn't release. So, what to do????

I began by removing the 4 bolts holding the bracket of the build platform to the lifting arm which released the arm from the bracket and allowed me to slide off the bracket. I then raised the lifting arm up to almost the top to make clear room to work below. I then removed the vat (w/building platform, etc.) and emptied the resin back into the jug (filtering, of course :thinking: ), and then addressed the problem of the build platform stuck to the FEP. This was the 2nd print today of the same part which I had printed successfully and removed not long before starting the new print run. I don't know the reason, but once the vat was empty, I could put my fingers under it and slightly push the FEP up thus breaking the seal between the FEP and the part - I was thus able to remove the parts without damaging the FEP.

[attachment=1]Failed FCD on Build Platf.jpeg[/attachment]

You can see the footprint of the part where suction held the part to the FEP.

I then proceeded to clean the vat and get it ready to print. In addition, the LCD screen & protective sheet on top were unaffected which was a major concern of mine -

[attachment=0]LCD Screen wSheet.jpeg[/attachment]

This will give me an opportunity to clean the vertical elevation rod before doing the normal resetting of the build platform (Z Lift 0 Setting).

Before I try printing this part again, I am still trying to figure out why this occurred - only 2 causes seem plausible:

1) The location (X/Y) of where the print was located within the printing parameters caused a suction to develop at that spot, or

2) Printing the center of the part directly on the build platform with no supports had created a vacuum when the print began printing the 1st layer on the FEP and this vacuum was just as strong as the resin layer on the build platform which brought things to a halt. I'm glad I was there in the shop when this happened. Had I not been, I'm sure the printer would have gone up in smoke at some point and that would have been an expensive failure!!

One item to note -l I did NOT take the plastic squeegee and drag it across the FEP to basically "clear" that area of the FEP prior to beginning the next print run. It's quite possible that had I done that, this incident would not have happened. I've printed other parts directly on the build platform and never had an issue with sticking to the FEP, as well. Always a first time... :doh_1:

I'm leaning towards redesigning the part adding in a few slots in the circular center disc in order to break a potential suction being created again. But, this is a gamble at best. Any ideas from other 3D designer/printer/modelers is welcomed.

|

|

|

|

Posted: Sat Sep 23, 2023 3:32 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

|

My friend Hank used to finely sand the platens to help adhesion. Many of the newer platens have a textured surface. I only rarely have this issue, but yes frustrating! be sure to clean out the vat!

My friend Hank used to finely sand the platens to help adhesion. Many of the newer platens have a textured surface. I only rarely have this issue, but yes frustrating! be sure to clean out the vat!

|

|

|

|

Posted: Fri Sep 08, 2023 2:41 am |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

|

While I am getting somewhere with the exposure settings today I have 4 failed prints. All items didn't stick to the plate not even the test print. I had some issues in the past but bow suddenly got much worse. I will lower my speed to just 1sec and increase bottom layer exposure to 50 sec as suggested by resin manufacturer. Otherwise I will use the second new vat I have see if the fep is damaged.

While I am getting somewhere with the exposure settings today I have 4 failed prints. All items didn't stick to the plate not even the test print. I had some issues in the past but bow suddenly got much worse. I will lower my speed to just 1sec and increase bottom layer exposure to 50 sec as suggested by resin manufacturer. Otherwise I will use the second new vat I have see if the fep is damaged.

|

|

|

|

Posted: Thu Sep 07, 2023 1:20 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

|

I have a jug of the Phrozen Aqua gray 8K. Perhaps I should try it again, with initial disappointment as to detail compared to the Rapid Black I returned to the old stuff. I recently ordered a new jug of RB which took 2 weeks to arrive, was not in factory box packaging, open and not full. EvilBay sometimes not a reliable source!

Pascal certainly has impressive results!

Tom

I have a jug of the Phrozen Aqua gray 8K. Perhaps I should try it again, with initial disappointment as to detail compared to the Rapid Black I returned to the old stuff. I recently ordered a new jug of RB which took 2 weeks to arrive, was not in factory box packaging, open and not full. EvilBay sometimes not a reliable source!

Pascal certainly has impressive results!

Tom

|

|

|

|

Posted: Tue Sep 05, 2023 10:33 am |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

Iceman 29 wrote: I've been using Eleggo standard grey V1 for a long time, then V2 now. It's not washable with water, only with alcohol, but it's cheap because it's not very expensive, and it doesn't smell.

I've made all my models with it. Anycubic resins are not great in general, too brittle, having used them at the beginning, 3 years ago.

The Phrozen Aqua-Gray 8K water washable resin seems to perform very well from what I've read. It's twice the price of other resins.

Which printer do you use? if you ask me i use Mono 4k [quote="Iceman 29"]I've been using Eleggo standard grey V1 for a long time, then V2 now. It's not washable with water, only with alcohol, but it's cheap because it's not very expensive, and it doesn't smell.

I've made all my models with it. Anycubic resins are not great in general, too brittle, having used them at the beginning, 3 years ago.

The Phrozen Aqua-Gray 8K water washable resin seems to perform very well from what I've read. It's twice the price of other resins.

Which printer do you use?[/quote]

if you ask me i use Mono 4k

|

|

|

|

Posted: Tue Sep 05, 2023 1:13 am |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

|

I've been using Eleggo standard grey V1 for a long time, then V2 now. It's not washable with water, only with alcohol, but it's cheap because it's not very expensive, and it doesn't smell.

I've made all my models with it. Anycubic resins are not great in general, too brittle, having used them at the beginning, 3 years ago.

The Phrozen Aqua-Gray 8K water washable resin seems to perform very well from what I've read. It's twice the price of other resins.

Which printer do you use?

I've been using Eleggo standard grey V1 for a long time, then V2 now. It's not washable with water, only with alcohol, but it's cheap because it's not very expensive, and it doesn't smell.

I've made all my models with it. Anycubic resins are not great in general, too brittle, having used them at the beginning, 3 years ago.

The Phrozen Aqua-Gray 8K water washable resin seems to perform very well from what I've read. It's twice the price of other resins.

Which printer do you use?

|

|

|

|

Posted: Mon Sep 04, 2023 4:46 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

So I have started testing a new resin. Its definitely not brittle and quite elastic. Using the same parameters as Anycubic resin I didnt get precise printings. I reduced the exposure but not much improvement. Then I mixed some Anycubic with the new resin at a ratio of 40-60. Results were better and still prints were not brittle. From left to right: Anycubic resin, Resione and mix of two products. Note one Oerlikon is missing a barrel already. However they are easier to design and print than Bofors.  So I have started testing a new resin. Its definitely not brittle and quite elastic. Using the same parameters as Anycubic resin I didnt get precise printings. I reduced the exposure but not much improvement. Then I mixed some Anycubic with the new resin at a ratio of 40-60. Results were better and still prints were not brittle. From left to right:

Anycubic resin, Resione and mix of two products. Note one Oerlikon is missing a barrel already. However they are easier to design and print than Bofors.

[url=https://ibb.co/FW4JFSQ][img]https://i.ibb.co/PYG4d72/IMG-20230904-211619.jpg[/img][/url]

|

|

|

|

Posted: Mon Sep 04, 2023 1:27 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

|

Thanks for the replies

What is the exposure times comparing to anycubic resin? Has anyone used the gray type? Looks like it has 24% elogation which is quite impressive for water resin.

For those in US there is a product from Ministry of Resin. Their claim that the water washable product is durable and non brittlle

Thanks for the replies

What is the exposure times comparing to anycubic resin? Has anyone used the gray type? Looks like it has 24% elogation which is quite impressive for water resin.

For those in US there is a product from Ministry of Resin. Their claim that the water washable product is durable and non brittlle

|

|

|

|

Posted: Wed Aug 09, 2023 1:35 am |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

|

Hank and I both began this printing adventure together, if at 3000 miles distance. I am currently also using the Phrozen Rapid Black water washable. I have tried a few other resins but this seems to reliably give quite good detail. For instance I am working up a couple of narrow gauge diesel locomotive shells with numerous grills on the sides. These printed very well indeed with 0.25mm openings on a .5 mm pattern.

Best regards: Tom

Hank and I both began this printing adventure together, if at 3000 miles distance. I am currently also using the Phrozen Rapid Black water washable. I have tried a few other resins but this seems to reliably give quite good detail. For instance I am working up a couple of narrow gauge diesel locomotive shells with numerous grills on the sides. These printed very well indeed with 0.25mm openings on a .5 mm pattern.

Best regards: Tom

|

|

|

|

Posted: Tue Aug 08, 2023 12:09 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

|

Mikegr -

I'm probably NOT the person to answer your last comment, but I've found that the Phrozen ABS-Like resins (gray & Rapid Black) produce quite pliable or non-brittle parts. I've read other comments that the Phrozen resins are more "watery" than the other brands and I have to agree. Possibly this is why the print time is quite a bit longer with the Phrozen resins than say either the Elegoo or Any Cubic.

Using the R.B. Black, my parts come out rather flexible and highly detailed, so this might be a consideration for your 2nd vat. Currently, this is all I'm using now and am quite pleased with the results. For larger parts that are generally thicker (1mm +) and dried/cured properly, these parts retain the solidity you would expect - such as for gun mount bodies, deck houses, etc.

Others may have their own favorites - perhaps there will be follow up commentary....!

Hank

Mikegr -

I'm probably NOT the person to answer your last comment, but I've found that the Phrozen ABS-Like resins (gray & Rapid Black) produce quite pliable or non-brittle parts. I've read other comments that the Phrozen resins are more "watery" than the other brands and I have to agree. Possibly this is why the print time is quite a bit longer with the Phrozen resins than say either the Elegoo or Any Cubic.

Using the R.B. Black, my parts come out rather flexible and highly detailed, so this might be a consideration for your 2nd vat. Currently, this is all I'm using now and am quite pleased with the results. For larger parts that are generally thicker (1mm +) and dried/cured properly, these parts retain the solidity you would expect - such as for gun mount bodies, deck houses, etc.

Others may have their own favorites - perhaps there will be follow up commentary....!

Hank

|

|

|

|

Posted: Tue Aug 08, 2023 9:10 am |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

My biggest problem with resin is that anycubic water washable is brittle especially when printing 1/700 parts. I am thinking of using my 2nd vat with normal resin for printing delicate parts. What would you suggest? ABS like or extra strong? I have also found 2 resins that look stronger at least in papers https://www.flashforgeshop.com/product/ ... tle?cID=42https://primacreator.com/collections/re ... 9920189542maybe these can work better so i dont have to change type of resin, what do you think? My biggest problem with resin is that anycubic water washable is brittle especially when printing 1/700 parts.

I am thinking of using my 2nd vat with normal resin for printing delicate parts. What would you suggest? ABS like or extra strong?

I have also found 2 resins that look stronger at least in papers

https://www.flashforgeshop.com/product/flashforge-lcd-405nm-uv-curing-water-washable-resin-1kg-bottle?cID=42

https://primacreator.com/collections/resin/products/primacreator-value-uv-dlp-dlp-resin-water-washable?variant=31879920189542

maybe these can work better so i dont have to change type of resin, what do you think?

|

|

|

|

Posted: Tue Aug 08, 2023 1:43 am |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

|

Mikegr -

Thanks for the comment on the resins. At this point, going back to a resin that has given proven results seemed only sensible given the costs in time/effort/money that can be involved.

Hank

Mikegr -

Thanks for the comment on the resins. At this point, going back to a resin that has given proven results seemed only sensible given the costs in time/effort/money that can be involved.

Hank

|

|

|

|

Posted: Mon Aug 07, 2023 1:49 pm |

|

|

|

|

|

| |

Post subject: |

Re: 3D printing |

|

|

BB62vet wrote: After a month or so of trying to get successful prints with the AnyCubic Black ABS Like resin and the Elegoo Gray ABS Like resin (v2) I've had enough of the failed prints and poor performance - even after soliciting assistance from others who use this printer or the same resins. I did get feedback from one member and tried his settings - they produced inconsistent results over several print runs. While a lot of this can be attributed to my own ineptitude using these resins and having the wrong settings, I don't have the time, money, or patience to continue with poor results. Therefore, I've returned to using the good old Phrozen ABS Like Rapid Black resin that I've had success with over the last couple years. Using Tom's current settings has produced 5 successful print runs in a row with better than 95% of the parts coming out complete and usable. Compared to less than 15% of usable parts with the other two resins, there is no reason to pursue their continued use. Just an update and to let others know that older resins DO work well with newer printers currently being sold. At least, this is the case for me. Again, there are other factors which determine how your prints will come out or not - orientation & support of the part and the inside room conditions (temp/humidity/etc.). Currently I'm working on getting small items reprinted for my destroyer project forecastle deck that needed slight tweaking in their design/size and this effort is coming together nicely. Refer to my USS STODDARD (DD-566) build for updates ( http://shipmodels.info/mws_forum/viewto ... 3#p1027683) Hank i used to go spearfishing in some places. Lately i go only in one place nearby because of lack of time. I noticed that after mulitple dives many secrets of the place and the fishes are discovered to me obviously if you quit one resin that used for sometime then its like going baxk almost to starting point. The longer you use the same resin/printer the more you discover [quote="BB62vet"]After a month or so of trying to get successful prints with the AnyCubic Black ABS Like resin and the Elegoo Gray ABS Like resin (v2) I've had enough of the failed prints and poor performance - even after soliciting assistance from others who use this printer or the same resins. I did get feedback from one member and tried his settings - they produced inconsistent results over several print runs.

While a lot of this can be attributed to my own ineptitude using these resins and having the wrong settings, I don't have the time, money, or patience to continue with poor results. Therefore, I've returned to using the good old Phrozen ABS Like Rapid Black resin that I've had success with over the last couple years. Using Tom's current settings has produced 5 successful print runs in a row with better than 95% of the parts coming out complete and usable. Compared to less than 15% of usable parts with the other two resins, there is no reason to pursue their continued use.

Just an update and to let others know that older resins DO work well with newer printers currently being sold. At least, this is the case for me. Again, there are other factors which determine how your prints will come out or not - orientation & support of the part and the inside room conditions (temp/humidity/etc.).

Currently I'm working on getting small items reprinted for my destroyer project forecastle deck that needed slight tweaking in their design/size and this effort is coming together nicely. Refer to my USS STODDARD (DD-566) build for updates (http://shipmodels.info/mws_forum/viewtopic.php?f=59&t=303053&p=1027683#p1027683)

Hank[/quote]

i used to go spearfishing in some places. Lately i go only in one place nearby because of lack of time.

I noticed that after mulitple dives many secrets of the place and the fishes are discovered to me

obviously if you quit one resin that used for sometime then its like going baxk almost to starting point. The longer you use the same resin/printer the more you discover

|

|

|

|

Posted: Mon Aug 07, 2023 12:23 pm |

|

|

|

|