@ Timmy: thank you! I had seen that link, but honestly I have problems to judge the quality from that picture. The main problem is that not always the same side of the model is shown to make a direct comparison possible. The picture gives the impression that PA12 and Smooth Fine Detail Plastic are similar. At least the surface of PA12 appears to be fine, but is it useful for finer details? I am not sure.

@ drasticplastic: you bought unfortunately the wrong printing quality. I agree that the cheapest quality makes the model unusable. These two models are actually good, if printed in a proper quality. I bought one of the smaller EFC from the same designer:

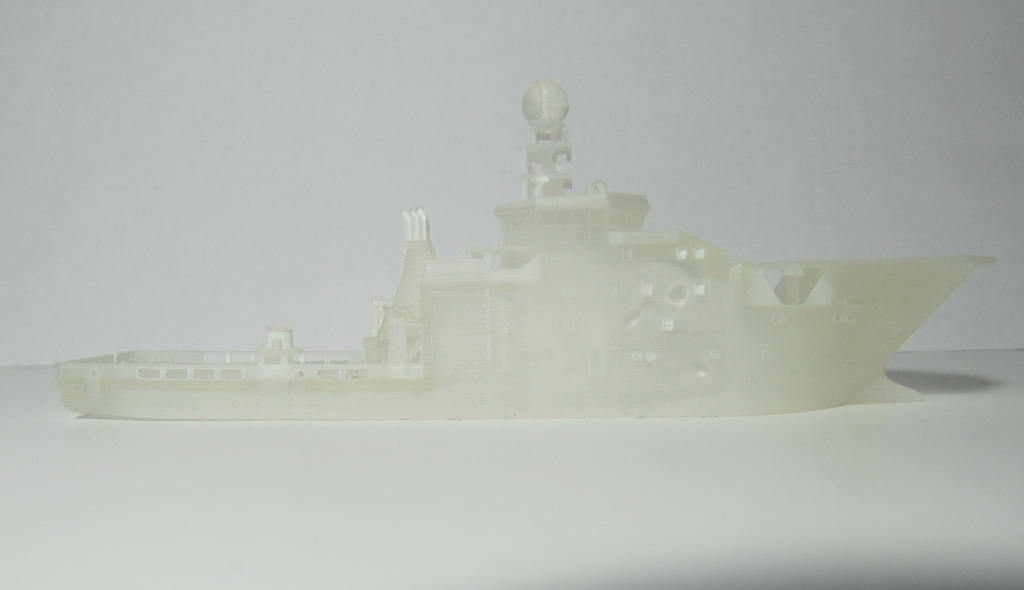

This is this model printed in Smooth Fine Detail Plastic:

https://www.shapeways.com/product/6DZJG3V5A/efc-1020-laker-ww1-freighter-1-600-1-700?optionId=62963900&li=shopsAll the models I bought, have to be additionally detailed, i.e. extra parts (scratch built or from other sources) have to be added. There are models, which consists of several parts including these freighters, which include parts for the masts (which I will replace with metal parts).

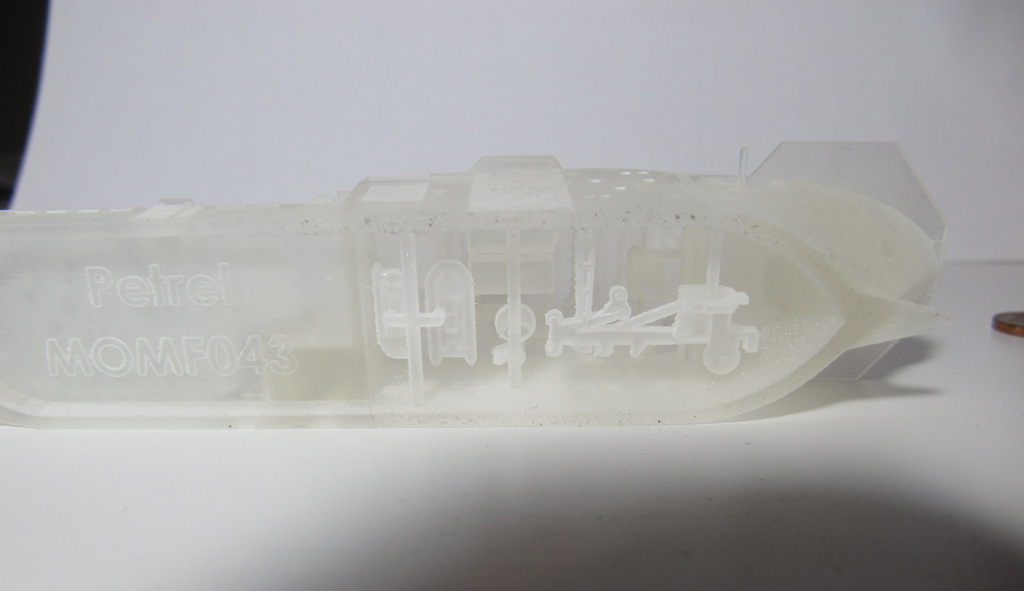

Here is another example for a 3D printed model consisting of several parts, RV Petrel by Masters of Military (photos showed it not cleaned, there is still wax visible):

http://www.modellmarine.de/index.php?option=com_content&view=article&id=5837:masters-of-military-forschungsschiff-rv-petrel-1700&catid=544:masters-of-military

http://www.modellmarine.de/index.php?option=com_content&view=article&id=5837:masters-of-military-forschungsschiff-rv-petrel-1700&catid=544:masters-of-military