It's hard to tell what you're dealing with without photos but I'll share some of my favorite tools with some explanation...

Sanding: My favorite sanders for ship models are the Step Sanders. They come in different sizes and grits. I would recommend the small three pack they sell. What's special about these is that the sanding strips use self adhesive to lock them in place. They fit perfectly on the handles. It allows you to do precise sanding in small areas. I've even taken it a step farther and made my own jig out of brass and cut small pieces of the self adhesive strips and stick them on the jig. Check out their web site at

http://www.stepsander.com

Home made sander for tight areas.

Scraping:

Scraping:Don't feel like you have to sand everything. Consider scraping small parts. You can do this with a small hobby knife or you can use some purpose built scrapers such as these from Voyager. They are really nice for rounding, smoothing, and truing masts and all other kinds of shapes. Scraping tends to leave a much smoother finish. I got mine from Hobby Link Japan.

Chisels:

Chisels:I have a couple of micro chisels that I find very handy for cleaning up unwanted flash, blemishes in the plastic, etc. I don't have this one but here's an example available from Hobby Link Japan.

[/URL]

Filling with plastic:My feeling is that you should always try and minimize the use of putty. When I have some nasty gaps due to poor fitting, etc. I use plastic strips to fill the gaps. I use a lot of .010, .015 and .020 plastic in different widths, cut to size, and glue into the gap. There there's much less to fill and a more solid construction.

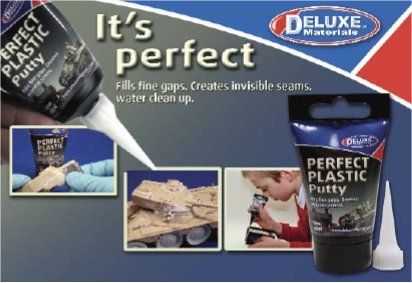

Filler/Putty:There are times when you need a filler. My favorite is Perfect Plastic Putty. The reason is that it is water based. Apply and you can use a wet brush to smooth it and clean up any excess. Sometimes it may take a couple of application but you'll be very happy with the results.

I hope this helps. I'm interested to see what others do as well.

Dave