Marijinn wrote:

>>> thorough and methodical approach <<<

me? nahhh...

you got the wrong guy - thorough and methodical, now that would be Georgy Pek!

now this is methodical and prepared!

viewtopic.php?f=59&t=163972&hilit=zs180#p707352

viewtopic.php?f=59&t=163972&hilit=zs180#p707352-- whereas I am rather more like making it up as I go along.

The next guy who follows can organise it all in a rational format !!

meanwhile--organised chaos continues in a rather more tangible manner at last

the ' funnel deck '....

there is a lot of work to do in this area; the manufacturers intention was that many dozens of small window frames are intended to be installed into apertures in the casting, however I saw a potential flaw in this plan when I first opened the box 18 months ago;

==> that being of getting everything flush and filled to perfection without messing up the window PE or the black colour behind and the chance of it all going horribly wrong and / or looking messy / bitty

Attachment:

P1230736.jpg [ 807.88 KiB | Viewed 1333 times ]

P1230736.jpg [ 807.88 KiB | Viewed 1333 times ]

When the window frames are installed it looked a like this -- the potential issues are self evident.

( note the 3-D printer step lines-- I was Idle... and did not clean them up as I was covering them.... !

ergo no need

)

Attachment:

P1230727.jpg [ 704.6 KiB | Viewed 1333 times ]

P1230727.jpg [ 704.6 KiB | Viewed 1333 times ]

more skilful (and patient !) people than I may elect to retro-fill and sand it all flush .

Attachment:

P1230728.jpg [ 551.21 KiB | Viewed 1333 times ]

P1230728.jpg [ 551.21 KiB | Viewed 1333 times ]

I elected to take a short cut ;

that of having the lifeboat deck faces made as photo-etched overlays

This has been pretty much wholly successful--but not alas without its own minor pitfalls (!)

But I digress--more of that later in this update ( cutting perfect PE ! )

Installing a lot of small window frames/ grilles is very time consuming...

I blacked the window area with a 3B soft lead pencil, and dropped in the window grilles

onto matt Humbrol varnish as the adhesive

( if at later inspection they are detected as crooked or wrong,

they are--unlike with glue-easily flicked off even when set .

)

Attachment:

P1230720.jpg [ 781.04 KiB | Viewed 1333 times ]

P1230720.jpg [ 781.04 KiB | Viewed 1333 times ]

Attachment:

P1230721.jpg [ 647.01 KiB | Viewed 1333 times ]

P1230721.jpg [ 647.01 KiB | Viewed 1333 times ]

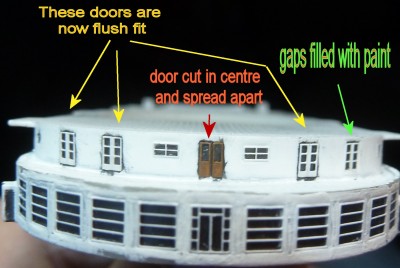

The First class verandah deck has some really nice PE doors in the kit--unfortunately these are slightly too wide for the apertures to sit in dead-flush (as they are on the real ship,) as is middle PE wooden double door, while it is nice,

....is a bit to narrow compared to photos

I would later widen this door; but in the meantime the apertures needed scraping out and making wider

it looks at this stage, neither promising or elegant!

Attachment:

P1230722.jpg [ 618.42 KiB | Viewed 1333 times ]

P1230722.jpg [ 618.42 KiB | Viewed 1333 times ]

It improved vastly with some PE ! ( timber door still to be painted and have stretched sprue put in centre split

Attachment:

P1230733.jpg [ 775.22 KiB | Viewed 1333 times ]

P1230733.jpg [ 775.22 KiB | Viewed 1333 times ]

The three small square windows either side would not be covered by the PE--

these suffered from being not ever so sharply cast alas

Attachment:

P1230741.jpg [ 566.98 KiB | Viewed 1333 times ]

P1230741.jpg [ 566.98 KiB | Viewed 1333 times ]

Attachment:

P1230770.jpg [ 916.64 KiB | Viewed 1333 times ]

P1230770.jpg [ 916.64 KiB | Viewed 1333 times ]

The cure here, was to to make my own seperate window frames of the thinnest

appropriate sized PE I could lay my hands on in my ( admittedly huge ) old PE stash

(WEM Koenig 1/350 ladders )

which would match the relief-etched frames of my custom PE

Attachment:

P1230752.jpg [ 677.08 KiB | Viewed 1333 times ]

P1230752.jpg [ 677.08 KiB | Viewed 1333 times ]

cutting these accurately was surprisingly tricky - I used the reflection of the PE in the cutting blade to get it mostly right

Attachment:

P1230762.jpg [ 669.23 KiB | Viewed 1333 times ]

P1230762.jpg [ 669.23 KiB | Viewed 1333 times ]

The slightly imperfect remainder was held in my flat tweezers ( padded with Tamiya tape )

and sanded with 1500 blunt sandpaper until flat

Attachment:

P1230767.jpg [ 682.84 KiB | Viewed 1333 times ]

P1230767.jpg [ 682.84 KiB | Viewed 1333 times ]

Attachment:

P1230731.jpg [ 501.04 KiB | Viewed 1333 times ]

P1230731.jpg [ 501.04 KiB | Viewed 1333 times ]

There was a missing window on the casting - above the entrance vestibule

I cut open my PE above the vestibule , inserted a section of window and closed the gap with s/s PE

Attachment:

aft deck windows a.jpg [ 517.42 KiB | Viewed 1333 times ]

aft deck windows a.jpg [ 517.42 KiB | Viewed 1333 times ]

Attachment:

P1230787.jpg [ 663.15 KiB | Viewed 1333 times ]

P1230787.jpg [ 663.15 KiB | Viewed 1333 times ]

Offering up my spare PE on the originally supplied funnel deck

( not the-replacement funnel deck )

was a wise move as it fitted well

BUT-- as there was a MINOR discrepancy between the the two castings ( o,2- 0.3 or so mm or so overall )

the new deck casting being fractionally smaller ( as evidenced by the packing piece at the bridge end)

Attachment:

P1230631.jpg [ 886.61 KiB | Viewed 1333 times ]

P1230631.jpg [ 886.61 KiB | Viewed 1333 times ]

(albeit it would have needed some of this this anyhow!!)

This threw out the window mullion centres ever so slightly but progressively

This required very very small amounts to be cut out of the PE to get the window mullions to align

Attachment:

P1230753.jpg [ 657.47 KiB | Viewed 1333 times ]

P1230753.jpg [ 657.47 KiB | Viewed 1333 times ]

Attachment:

P1230756.jpg [ 683.68 KiB | Viewed 1333 times ]

P1230756.jpg [ 683.68 KiB | Viewed 1333 times ]

Attachment:

P1230761.jpg [ 822.62 KiB | Viewed 1332 times ]

P1230761.jpg [ 822.62 KiB | Viewed 1332 times ]

The cuts were closed off with stretched sprue which after the first coat of paint will be pared

and sanded flush before the next coat.

Attachment:

P1230789.jpg [ 530.84 KiB | Viewed 1333 times ]

P1230789.jpg [ 530.84 KiB | Viewed 1333 times ]

The entrance vestibule had window frames cut down to size from spare items of the fwd winter garden

( at the bows)windows.

Attachment:

P1230793.jpg [ 617.16 KiB | Viewed 1333 times ]

P1230793.jpg [ 617.16 KiB | Viewed 1333 times ]

This area is poorly photographed; and is not easily visible in aerial photos either as the after-most davit and boat usually obscures the view

Attachment:

20190107_124056.jpg [ 198.14 KiB | Viewed 1333 times ]

20190107_124056.jpg [ 198.14 KiB | Viewed 1333 times ]

The casting accurately portrays the hollow in the outside wall ==> kudos!

Attachment:

20190107_124154 - Copy.jpg [ 231.13 KiB | Viewed 1333 times ]

20190107_124154 - Copy.jpg [ 231.13 KiB | Viewed 1333 times ]

the solid part of the vestibule I made of vinyl tape

Attachment:

P1230792.jpg [ 671.09 KiB | Viewed 1333 times ]

P1230792.jpg [ 671.09 KiB | Viewed 1333 times ]

Attachment:

P1230793.jpg [ 617.16 KiB | Viewed 1333 times ]

P1230793.jpg [ 617.16 KiB | Viewed 1333 times ]

Note the hollow to the outside wall has now been added

Attachment:

P1230800.jpg [ 747.77 KiB | Viewed 1332 times ]

P1230800.jpg [ 747.77 KiB | Viewed 1332 times ]

well that is it so far -- some more updates as they happen.

More modelling now--less thinking about it !

JB